Cast Baslat mai liyi bututu mai raba bututun ciyar da bututu Don Tsarukan Gudanar da Kayan Kaya

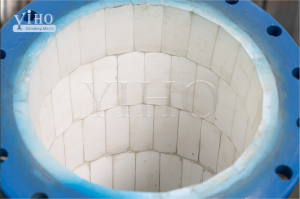

An yi bututun ƙarfe na simintin simintin gyare-gyare tare da bututun basalt mai liyi, bututun ƙarfe mai sutura da turmi cimin cimin tsakanin yadudduka biyu, yana saita juriyar lalacewa da juriyar lalata bututun dutse, taurin bututun ƙarfe da ƙarfafawar turmi siminti a daya.Inganta ƙarfin samfurin na daidaita yanayin aiki daban-daban masu rikitarwa.A lokaci guda ta yin amfani da turmi siminti a matsayin kayan cikawa, zai iya yin bututun ciki a cikin tsaka-tsakin alkaline, don haka saman bututun ƙarfe zai samar da fim mai tsabta don hana lalata.Cast basalt lined bututun ƙarfe ba wai kawai yana jure lalacewa da lalata ba, akan babban matsin lamba, amma kuma dacewa kuma mai aminci don jigilar kaya.

Za a iya raba bututun basalt ɗin zuwa bututu madaidaiciya, gwiwar hannu, bututu mai tafarki uku (hanyoyi huɗu) da bututun diamita mai canzawa, da sauransu.

Kyakkyawan aikin bututun ƙarfe na simintin simintin ƙarfe shine cewa yana saita ƙarfin bututun ƙarfe, juriyar juriyar bututun basalt, kankare turmi siminti ɗaya.

Wannan yana haɓaka ƙarfin daidaita samfuran a cikin yanayin aiki mai rikitarwa.A lokaci guda.An zaɓi turmi siminti azaman kayan cikawa kuma wannan na iya yin saman saman bututun ƙarfe a cikin matsakaicin alkali.Don haka saman bututun ƙarfe yana haifar da fina-finai masu tsarkakewa.Wadannan fina-finai na iya hana yin tsatsa.

Ƙayyadaddun bayanai

• Ƙarƙashin Ƙarƙashin Ƙaƙwalwa: 32 zuwa 600 mm

• Girman Kauri: 20 zuwa 30 mm

• Tsawon: 500 mm

Siffofin fasaha Na Basalt Material

Kayan Kimiyya

| SiO2 | Farashin AL2O2 | Fe2O3 | TiO2 | CaO | MgO | K2O | Na 2O | FeO | P2O5 |

| 43.13-44.12 | 12.5-13.52 | 8.64-9.5 | 2.02-2.62 | 9.05-10.22 | 8.65-10.47 | 1.4-1.75 | 4.62-5.28 | 4.82-6.25 | 1.1-1.38 |

Dukiyar jiki

| Abu | Fihirisa |

| Yawan yawa | 3.0g/cm3 |

| Ƙarfin Ƙarfi | 286Mpa |

| Karfin Lankwasawa | ≥60Mpa |

| Ƙarfin Tasiri | 1.36KJ/M2 |

| Abrasion | 0.07g/cm2 |

| Webster Hardness | ≥720kg/mm2 |

| Modulus na elasticity(25 ℃) | 1.67×105Mpa |

| Ƙimar haɓakawa(25 ℃ ~ 60 ℃) | 8.92×10-6 |

| 95% -98% H2SO4 | ≥98% |

| 20% H2SO4 | ≥94% |

| 20% NaOH | ≥98% |

Amfanin Bututun Basalt

Dangane da buƙatun abokin ciniki tare da fasahar samar da basalt kuma za mu iya ba da takamaiman bayani dalla-dalla da nau'i daban-daban don saduwa da buƙatar abokin ciniki.

• Juriya na juriya: Yayin da ƙarin kayan ke wucewa akan Cast Basalt yana samun gogewa ta haka yana rage juzu'i.Cast Basalt yana haɓaka sabis bayan an goge shi.Wetting kuma yana inganta aikinsa a aikace-aikace masu amfani.

•Juriya Tasiri: Tsayayyar Tasirin Kai tsaye a digiri 90 yana da ƙasa kamar duk sauran yumbu, amma ana iya ƙarawa tare da shigarwa mai dacewa ta hanyar rage kusurwar tasiri.Cast Basalt shine mafi kyawun duk inda zamewa abrasion ya kasance.Bugu da ƙari, ƙarfin tasirin waje na haɗaɗɗen bututun basalt koyaushe yana fiye da na bututun Ni-hard.

•Juriya na Chemicale : Cast Basalt kusan yana da cikakken juriyar acid/alkali (sai dai Hydrofluoric Acid) don haka yana jure lalata.

•Nauyi da Girma: Ana samun Tiles na Basalt a murabba'in siffa na yau da kullun na kauri 200 x 200 x 30 mm, suna auna kusan.90 kg/m²;yayin da tanƙwara da bututu ana yin layi ta amfani da Basalt Silinda masu girma dabam dabam daga 50NB har zuwa 500NB.

•Zazzabi: Cast Basalt yana jure yanayin zafi har zuwa 4500 oC

Amfani da simintin gyare-gyaren bututun ƙarfe na basalt

Ana amfani da bututun ƙarfe na Cast basalt a cikin aikace-aikace inda abrasion da lalacewa sune manyan ƙalubale.