Sanya Lining Mai jure Cyclone Anyi daga Alumina

Cikakken bayanin

Babban jikin guguwar ya ƙunshi na'ura mai ragewa ko siffa mai siffa mai mazugi mai matsewa daga babban diamita zuwa ƙarami ƙasa da tsayinsa.

Saka Maganin Juriya don Cyclones

Tun da kayan da aka raba a cikin guguwa suna da banƙyama sosai, yana da mahimmanci a sami rufin guguwa wanda ya dace da tsangwama na aikin.Za'a iya amfani da Alumina mai Tsabtataccen Tsafta don haɓaka rayuwar aikin guguwa da aiki kuma ana iya yin su da siffa ta al'ada don dacewa da duk geometries;daga aikin bututun da ke kaiwa zuwa mashigai, mai gano vortex da kuma koli, zuwa ga madaidaicin zuciya na guguwar.

Abubuwan Abubuwan Cyclone galibi waɗanda ke ƙarƙashin Sawa

Akwai abubuwa da yawa a cikin taron guguwar da ke ƙarƙashin yanayin lalacewa.Taylor Ceramic Engineering na iya samar da yawancin waɗannan a cikin kayan da ba su da ƙarfi don tsawaita rayuwar abubuwan.Wasu daga cikin sassan da muke samarwa galibi sun haɗa da:

Silindrical & Rage Layi

· Masu shiga

· kantuna

· Matsala

· Sakawa

• Sassan Mazugi na Sama, Tsakiya & Ƙasa

· Masu gano Vortex

· Kusan duk wani saman da ke fama da lalacewa!

Saka Tsararrun Rubutun Juriya

Za'a iya amfani da dabaru iri-iri masu jure lalacewa;daga monolithic abun da ake sakawa zuwa sassan tiled.

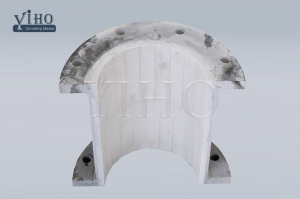

Sassan monolithic

YIHO yana da matsayi na musamman don samun damar kera kanana da manyan sifofin monolithic a cikin gajeren lokaci.Ana iya yin waɗannan sassan na al'ada don dacewa da ainihin buƙatun ku.

Sassan monolithic suna da fa'ida cewa sun fi sauri don shigarwa, don haka rage raguwa.

Sassan Tiled

Saboda yawancin wuraren da ke da alaƙa da taron guguwa suna lanƙwasa ne, Taylor Ceramic Engineering yana iya yin injin fale-falen fale-falen da suka dace da ainihin siffar da ake buƙata.

Fale-falen fale-falen buraka akan filaye masu lanƙwasa sau da yawa suna barin jerin filaye masu haske a kewayen saman ciki na guguwar.Wannan ba wai kawai ya katse kwararar kayan ba amma yana ƙara lalacewa a saman fale-falen fale-falen don haka yana rage rayuwar kayan aiki.Koyaya, yin amfani da fale-falen fale-falen buraka na injiniya waɗanda suka dace da sifar da ake buƙata yana rage raguwa kuma yana haɓaka kwararar kayan kuma don haka ingancin kayan aiki.

| Kashi | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Yawan yawa | ≥3.50g/cm3 | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 | ≥3.83g/cm3 | ≥4.10g/cm3 | ≥5.90g/cm3 |

| Shakar Ruwa | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% |

| HV 20 | ≥900 | ≥950 | ≥ 1000 | ≥ 1100 | ≥ 1200 | ≥1350 | ≥ 1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Lankwasawa Ƙarfin MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Ƙarfin matsawa MPa | ≥970 | ≥ 1050 | ≥ 1300 | ≥ 1600 | ≥1800 | ≥2000 | / |

| Karya Tauri Kic MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Saka Girman | ≤0.28cm3 | 0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |